Struggling with production delays or inaccurate inventory? Optify's Manufacturing ERP system gives you complete control over production, inventory, costs, and quality - all in one place.

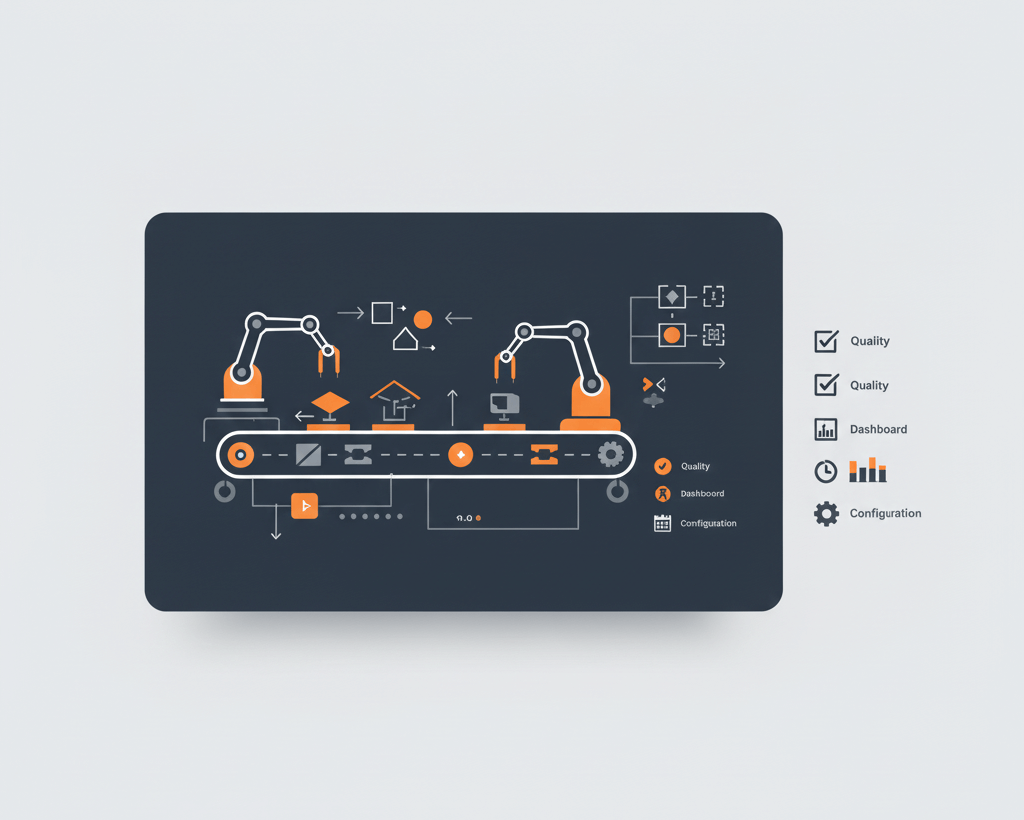

Tools specifically designed to streamline factory operations

Create detailed BOMs with multiple levels and variations. Track components, sub-assemblies, and finished goods with full version control.

Manage the complete production lifecycle from planning to completion. Track status, material consumption, labor hours, and machine usage in real-time.

Automatic calculation of production costs including materials, labor, and overhead. Compare planned vs actual costs to identify variances and improve profitability.

Maintain optimal inventory levels with automatic reorder points. Track raw materials, work-in-progress, and finished goods across multiple warehouses.

Get instant insights into production efficiency, costs, and inventory levels. Make data-driven decisions with easy-to-understand dashboards.

Implement quality checks at every production stage. Track defects, reworks, and scrap to continuously improve your processes.

Unlike expensive imported systems, Optify is specifically designed for Egyptian factories at an affordable price point, with local support and English/Arabic interface.

Eliminate production bottlenecks with real-time workshop visibility. Track orders from start to finish with automatic status updates.

Maintain optimal inventory levels with automatic tracking. Raw materials are automatically deducted when production orders are completed.

Identify cost-saving opportunities with detailed production costs. Compare planned vs actual material usage to reduce waste.

Implement quality checkpoints throughout the production process. Track defects and apply corrective actions.

Whether you run a small workshop or a large production facility, we have the right tools for you

Ideal for factories assembling distinct products like machinery, furniture or electronics. Track individual components through the production process.

Ideal for food, chemicals, pharmaceuticals and other industries that produce based on formulas rather than discrete parts.

Join hundreds of factories already improving their operations with Optify

See how Optify ERP empowers Egyptian manufacturers

Join over 50 Egyptian factories that have already improved their processes with Optify. Start with a free trial and see the difference in just 30 days.